If you leave paved roads with your vehicle, you should adjust the tire pressure in many cases. Tire pressure control systems can be used to reduce and increase tire pressure comfortably and quickly, even with large-volume tires. However, the latter can be quite expensive to purchase and install. We therefore decided to build a simple system ourselves and gain experience with it.

To this end, we have set ourselves the following goals:

- All four tires should be able to be operated at the same time

- It should be possible to both increase and decrease the pressure to an adjustable value

- After connection to the compressed air source and the tires, the system should work automatically, especially stop automatically, in order to avoid damage caused by too high or too low pressures

- Compressed air sources should be able to be used flexibly (e.g. truck compressed air system, compressor, workshop/filling station, etc.)

- The system should be compact and portable to transport.

- The system should not be tied to a specific vehicle.

To implement the prototype, we only bought cheap products from large internet retailers. The total cost of the parts was around EUR 250.

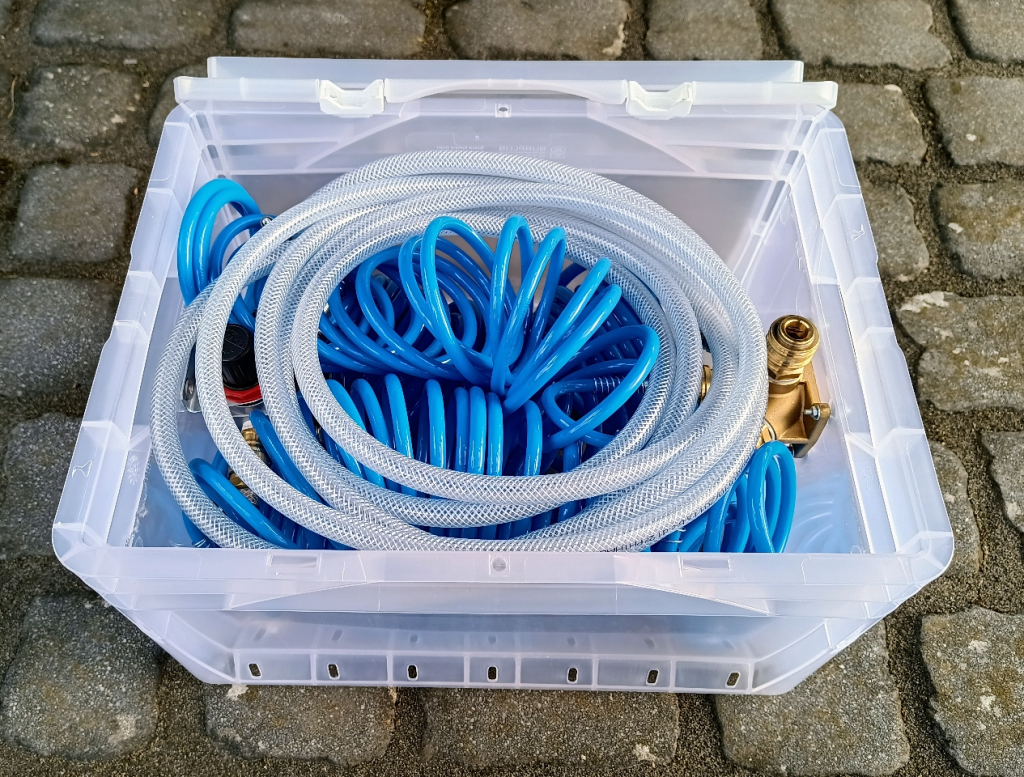

Here is a photo sequence of the prototype during the first test:

- The system is placed at the rear of the vehicle

- The system's Eurobox is opened

- The pressure line to the compressed air connection is removed ...

- ... and connected to the supply line for the trailer brake (maximum pressure there approx. 8.5 bar).

- The desired target pressure is set on the pressure reducing valve.

- The spiral pressure hoses to the rear tires are connected.

- The spray pressure hoses for the front tires are connected.

- The system now regulates the pressure in the four tires to the set pressure.

- Depending on the tire valve, the appropriate adapter is used.

In the first two test runs, the tire pressure was reduced twice from approx. 7 bar to 3.5 bar and then increased again to 7 bar. Both decreasing and increasing the pressure took about 10 minutes. When increasing the pressure, the engine speed was increased to approx. 1000 rpm in order to increase the delivery capacity of the air compressor. The tire dimension during the test was 385/65 R 22.5.

Remarks:

- The standard compressed air connection of the truck can also be used as a source of compressed air or any other compressor with a suitable capacity (suction volume and maximum pressure)

- The short side walls of the Eurobox were reinforced with an additional layer of plastic to increase the stability of the parts screwed on there. Time will tell if this is enough. If not, a more expensive Eurobox with more stable side walls or an aluminum box can be used.

Parts List:

- Pressure reducer with secondary ventilation:

https://www.amazon.de/dp/B07FMYKWMF?psc=1&ref=ppx_yo2ov_dt_b_product_details - Another pressure reducer, of which only a few parts (e.g. compressed air couplings) are required:

https://www.amazon.de/dp/B09WTSK9BR?psc=1&ref=ppx_yo2ov_dt_b_product_details - Compressed air distributor fourfold:

https://www.amazon.de/dp/B08RZ92FB8?psc=1&ref=ppx_yo2ov_dt_b_product_details - Compressed air adapter coupling supply line trailer

https://www.amazon.de/dp/B075DDTYTW?psc=1&ref=ppx_yo2ov_dt_b_product_details - Spiral compressed air hose 10m:

https://www.amazon.de/dp/B00103796O?psc=1&ref=ppx_yo2ov_dt_b_product_details - Compressed air spiral hose 5m:

https://www.amazon.de/dp/B001KOKJI8?psc=1&ref=ppx_yo2ov_dt_b_product_details - Pneumatic clutch: https://www.amazon.de/gp/product/B00BQWM2TI/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

- Pneumatic clutch:

https://www.amazon.de/gp/product/B096PC6SLX/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1 - valve clamp:

https://www.amazon.de/dp/B00JN65XAE?psc=1&ref=ppx_yo2ov_dt_b_product_details - hose clamps:

https://www.amazon.de/dp/B08B67JR96?psc=1&ref=ppx_yo2ov_dt_b_product_details - pressure hose

https://www.amazon.de/dp/B07B4H9L8P?psc=1&ref=ppx_yo2ov_dt_b_product_details - silicone grease

https://www.amazon.de/dp/B07TY7BPKT?psc=1&ref=ppx_yo2ov_dt_b_product_details - Adapter for truck standard compressed air connection

https://www.amazon.de/dp/B07MQ6L9YT?psc=1&ref=ppx_yo2ov_dt_b_product_details - Euro box 40x30x22 cm

https://www.obi.de/aufbewahrungsboxen/eurobox-system-box-vollwand-mit-griffmulden-40-x-30-x-22-cm-transparent/p/4204921 - Euro box hinged lid

https://www.obi.de/aufbewahrungsboxen/eurobox-system-schanierdeckel-transparent-30-cm-x-20-cm/p/4244000

We will now test the system further and then report back.

Leave a Reply